The Essential Guide to Parts of Piston Ring

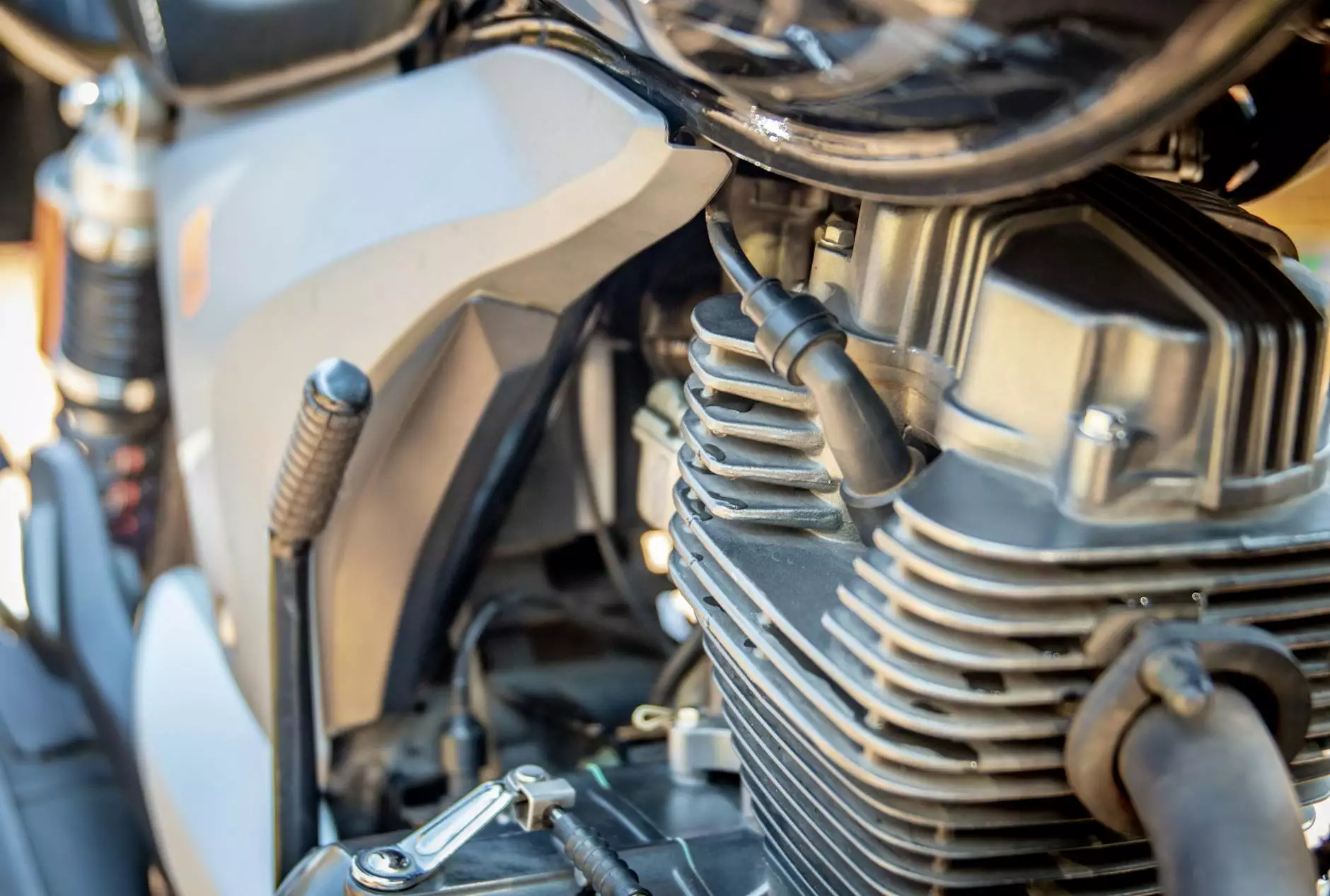

In the world of diesel engines, understanding the parts of piston ring is crucial for achieving optimal performance and longevity. Whether you are a seasoned mechanic or a business owner in the automotive industry, comprehending the intricacies of piston rings can be a game-changer for your operations. In this comprehensive guide, we will delve into everything you need to know about piston rings, from their anatomy and functions to maintenance tips and troubleshooting advice, specifically tailored for businesses operating in the Diesel Engine Parts and Spare Parts Suppliers sectors.

What Are Piston Rings?

Piston rings are essential components of an engine that perform several vital functions. They are circular rings made primarily of cast iron or steel, and they fit into grooves around a piston. Each engine typically has two or three piston rings, depending on the design and requirements of the engine. Here’s a breakdown of their primary roles:

- Sealing: Piston rings create a seal between the piston and the cylinder wall, preventing the escape of combustion gases.

- Heat Transfer: They assist in transferring heat from the piston to the cylinder wall, ensuring efficient cooling.

- Oil Control: Certain types of rings manage the lubrication oil, ensuring the right amount lubricates the piston and cylinder without excessive oil burning or leakage.

The Anatomy of Piston Rings

To fully appreciate the function of piston rings, it's important to understand their anatomy. Each piston ring is composed of several parts:

1. Top Ring

The top ring, often referred to as the compression ring, is the most critical component. It is designed to withstand high temperatures and pressures created during combustion. Its primary purpose is to seal the combustion chamber, preventing exhaust gases from leaking into the crankcase.

2. Intermediate Ring

The intermediate ring, sometimes known as the scraper ring, serves a dual purpose. It helps to scrape any excess oil from the cylinder wall and also contributes to sealing the combustion chamber.

3. Oil Control Ring

The oil control ring's primary function is to regulate oil distribution on the cylinder wall. It ensures that just the right amount of oil is maintained for lubrication while preventing excess oil from entering the combustion chamber, which can lead to increased emissions and oil consumption.

Types of Piston Rings

Understanding the different types of piston rings is essential for any business dealing with diesel engine parts:

- Cast Iron Rings: Known for their durability and wear resistance, these rings are commonly used in diesel engines for their strength.

- Steel Rings: These rings are often found in high-performance engines due to their strength and ability to withstand extreme temperatures.

- Chrome-plated Rings: Chrome plating adds a layer of toughness and reduces friction, contributing to better fuel economy.

Importance of Piston Rings in Diesel Engines

Piston rings are not merely accessories; they are indispensable elements of functional diesel engines. Their effectiveness directly influences the overall performance, fuel efficiency, and emissions of the engine. Here's why they are crucial:

1. Improved Efficiency

Well-functioning piston rings ensure that combustion gases are effectively sealed within the cylinder, leading to improved efficiency. This efficiency translates to better fuel economy, which is a significant concern for spare parts suppliers and customers alike.

2. Reduced Emissions

With proper sealing, combustion gases do not escape, which means less unburned fuel and lower emissions. This is essential for meeting modern environmental regulations, which are increasingly strict.

3. Enhanced Engine Life

By maintaining optimal temperatures and reducing wear on the piston and cylinder wall, high-quality piston rings contribute to the longevity of the engine. This payoff is especially valuable for businesses focused on delivering quality and reliability.

Maintenance Tips for Piston Rings

For those in the business of diesel engine parts, knowing how to maintain piston rings can save you and your customers time and money. Here are some maintenance tips:

- Regular Inspections: Regularly inspect the condition of piston rings during routine engine maintenance to identify wear and tear before they lead to more significant issues.

- Oil Quality: Use high-quality engine oil to reduce the chances of sludge buildup and to ensure effective lubrication.

- Correct Installation: Ensure that piston rings are installed correctly according to manufacturer specifications to avoid operational issues.

- Monitor Engine Performance: Keep an eye on your engine's performance metrics. An increase in oil consumption or a decrease in power can signify piston ring problems.

Troubleshooting Common Piston Ring Issues

Even with proper maintenance, issues can still arise. Here are some common symptoms of piston ring problems along with troubleshooting solutions:

1. Increased Oil Consumption

If you notice that your engine is consuming more oil than usual, it may indicate a problem with the oil control ring. In such cases, inspect the piston rings for wear and consider replacement if necessary.

2. Excessive Smoke from Exhaust

When white or blue smoke is emitted from the exhaust, it often signals that oil is burning in the combustion chamber. This can be traced back to worn or damaged piston rings.

3. Loss of Power

A noticeable drop in engine power might be a sign of inadequate sealing by the piston rings. This may require a detailed inspection and potentially a ring replacement.

Conclusion: The Vital Role of Piston Rings in Diesel Engines

In summary, the parts of piston ring play an essential role in the performance and longevity of diesel engines. Understanding their functions, types, maintenance, and troubleshooting can empower businesses like client-diesel.com to provide better services and foster stronger customer relationships. By ensuring optimal maintenance and being aware of potential issues, businesses can enhance engine performance, efficiency, and satisfaction among their clients.

With the right knowledge and attention to detail, you can ensure that piston rings are always operating at peak performance, driving success in the competitive world of Diesel Engine Parts and Spare Parts Suppliers.